Innovative Industrial Pumps

Engineered for Excelence

Leveraging insights from millions of operational hours, Magnevo™ pumps are the culmination of our commitment to innovation. Our state-of-the-art sealless centrifugal magnetic-drive pumps are designed to excel in the most demanding industrial environments.

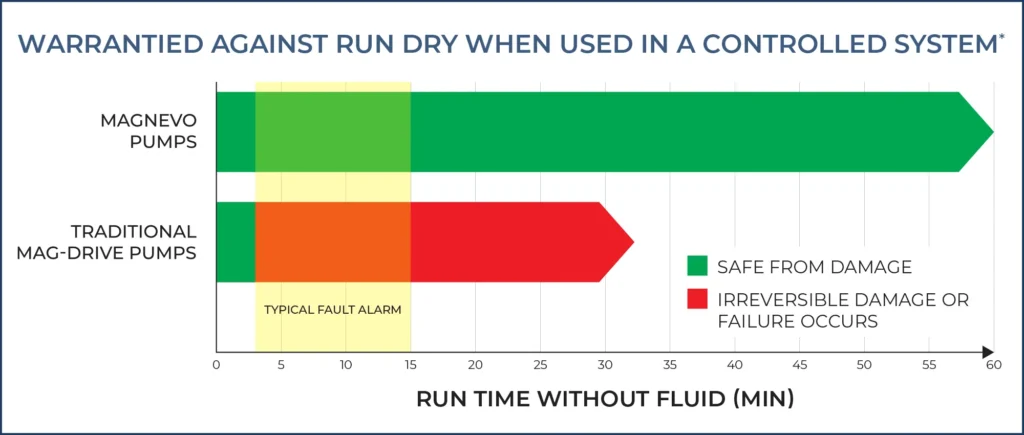

Warrantied Against Run Dry

Running a pump dry, without fluid for cooling, will cause premature wear and failure. Friction builds rapidly, generating intense heat that can melt or severely damage internal components. Traditional magnetic-drive pumps can fail in as little as three minutes, and even brief periods of running dry can cause cumulative damage that leads to premature pump failure.

Magnevo sealless magnetic-drive pumps offer extreme Run-Dry Protection thanks to extremely low heat generation. The patent-pending design incorporating proprietary materials creates less heat and dissipates it efficiently for extended life span.

Here’s why it matters: When a fluid system doesn’t receive the necessary fluid, it can lead to several problems including reduced performance, overheating, system failure, and potential damage to components. These issues can occur because the fluid is crucial for lubricating moving parts and maintaining the proper operating temperature of the system.

Magnevo’s new patent-pending Run-Dry Protection technology allows the pump to withstand run-dry conditions far beyond the typical system shut-down time when fluid is not present. This extended Run-Dry Protection prevents the risk of damage or failure during this vulnerable period. While Magnevo pumps have superior Run-Dry Protection, they cannot run dry forever. A controlled system that can shut down operations within 15 minutes of a run-dry situation due to pressure, flow, or heat of other systems will help extend the life of the pump and the fluid system.

Magnevo Pumps are designed, assembled, and quality-control tested in-house by our engineering and manufacturing teams at our headquarters in USA. Magnevo is backed by a 2-year parts and labor warranty.*

*Magnevo Pumps are warrantied against run dry when used in a controlled fluid circuit. Magnevo series MC4, MC6, and MC10 have a warranty period of 60 minutes, and Magnevo series MC13 and MC15 have a warranty period of 15 minutes.*

View our full Warranty terms and conditions for details.

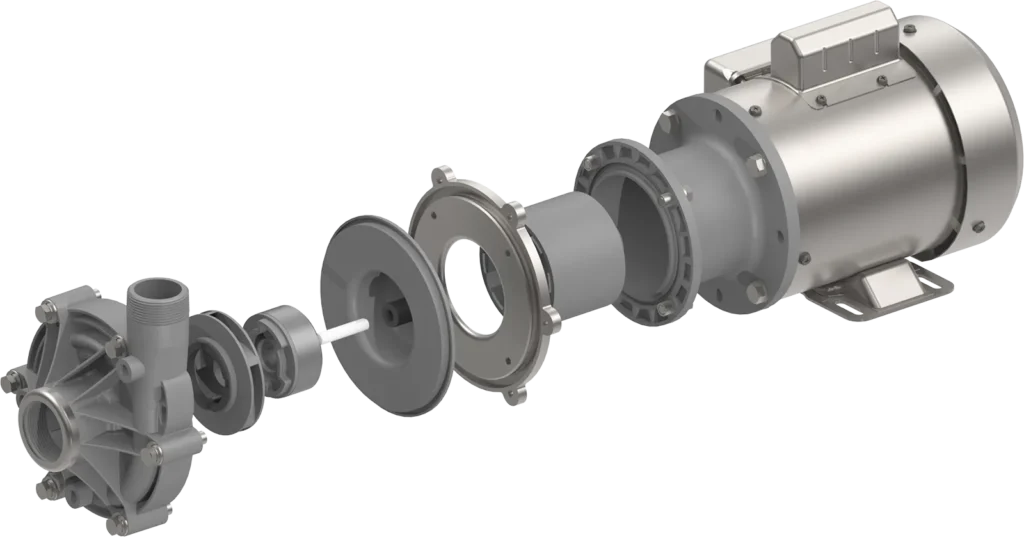

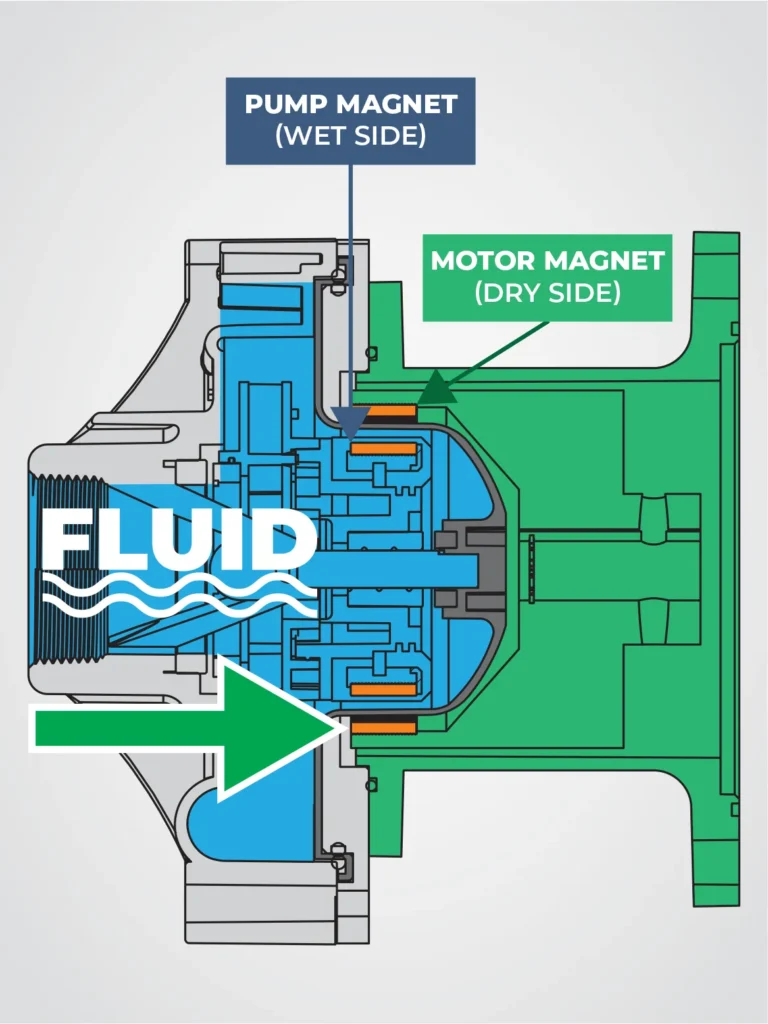

Sealless magnetic drive

Magnevo Pumps’ sealless magnetic-drive pumps offer superior performance and reliability. The unique magnetic coupling design eliminates the need for mechanical seals, which are prone to failure in corrosive environments. This innovative technology ensures minimal downtime and reduced maintenance costs. Furthermore, the pumps’ high efficiency and ability to handle fluctuating flow rates and pressures make them an excellent choice for industrial fluid transfer applications.

Key features for enhanced efficiency and productivity

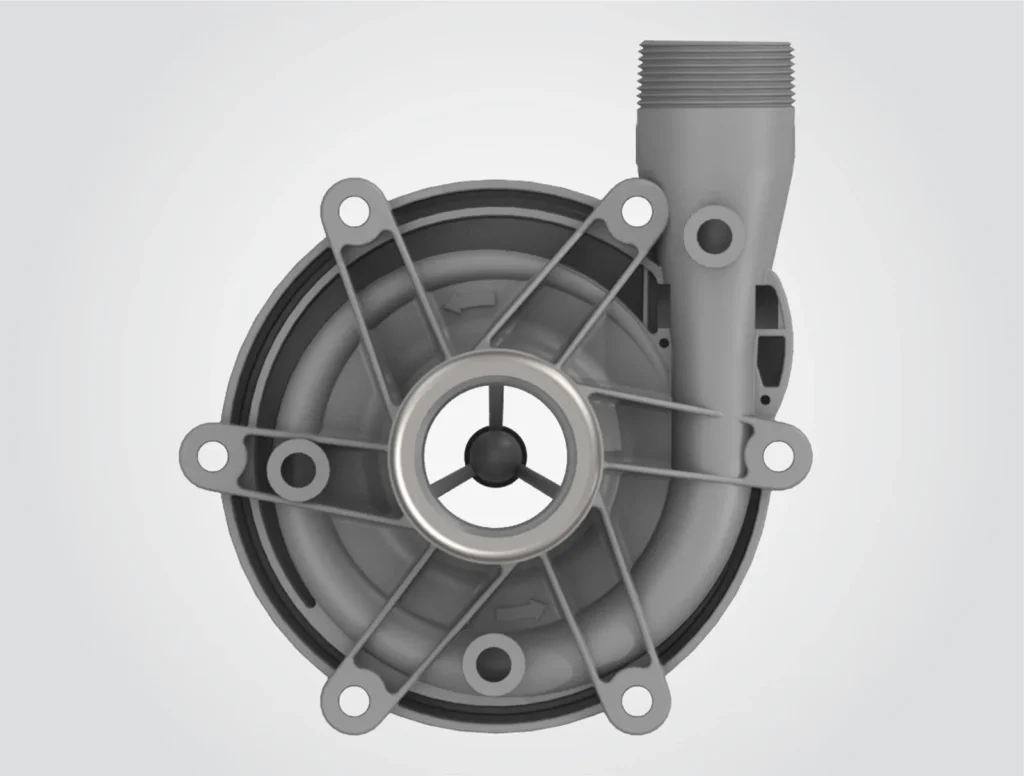

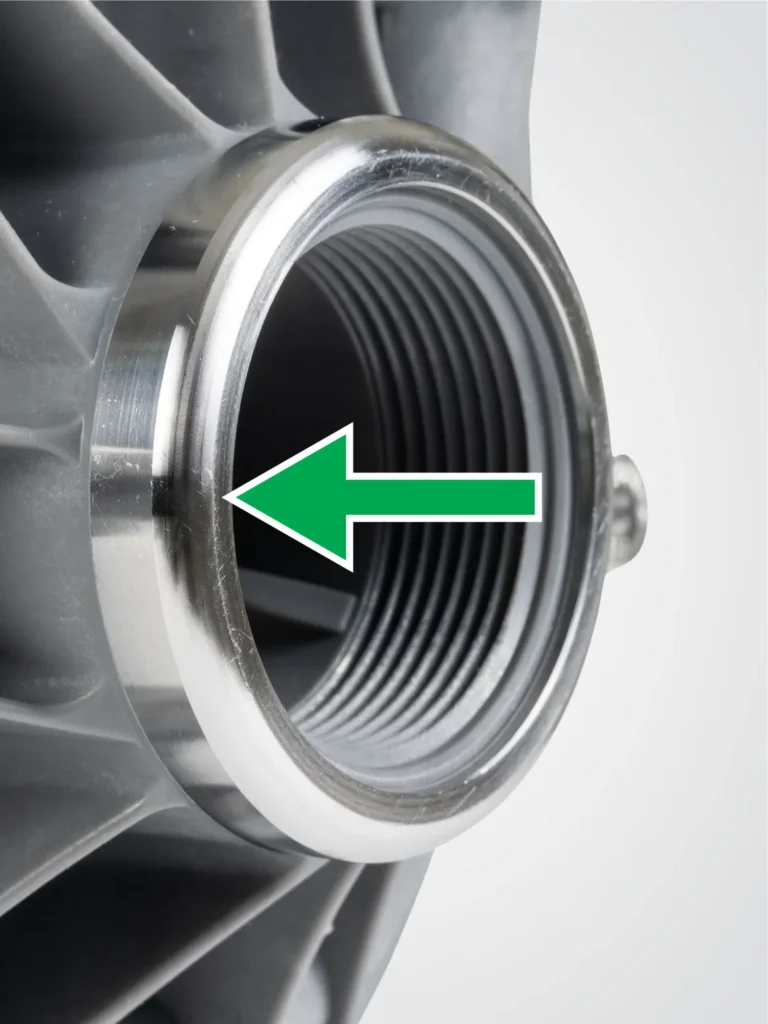

Reinforced inlet prevents cracking

A reinforced inlet ring is molded into the pump head and made from (316L) stainless to provide extra strength at the connection point to prevent cracking (patent pending).

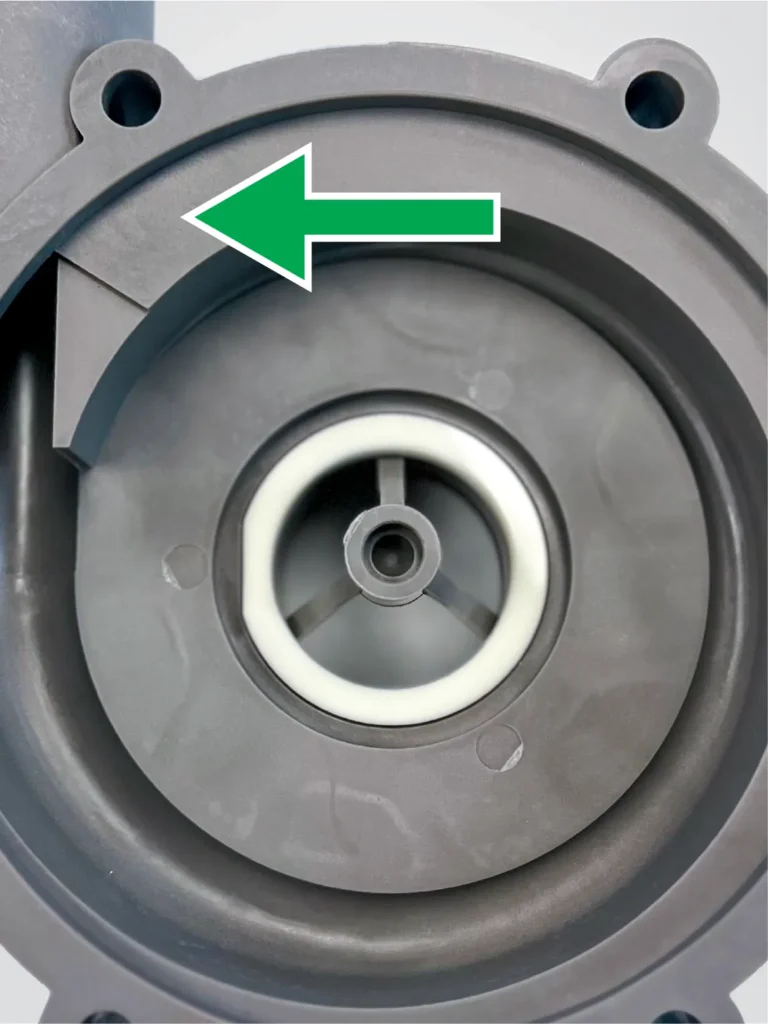

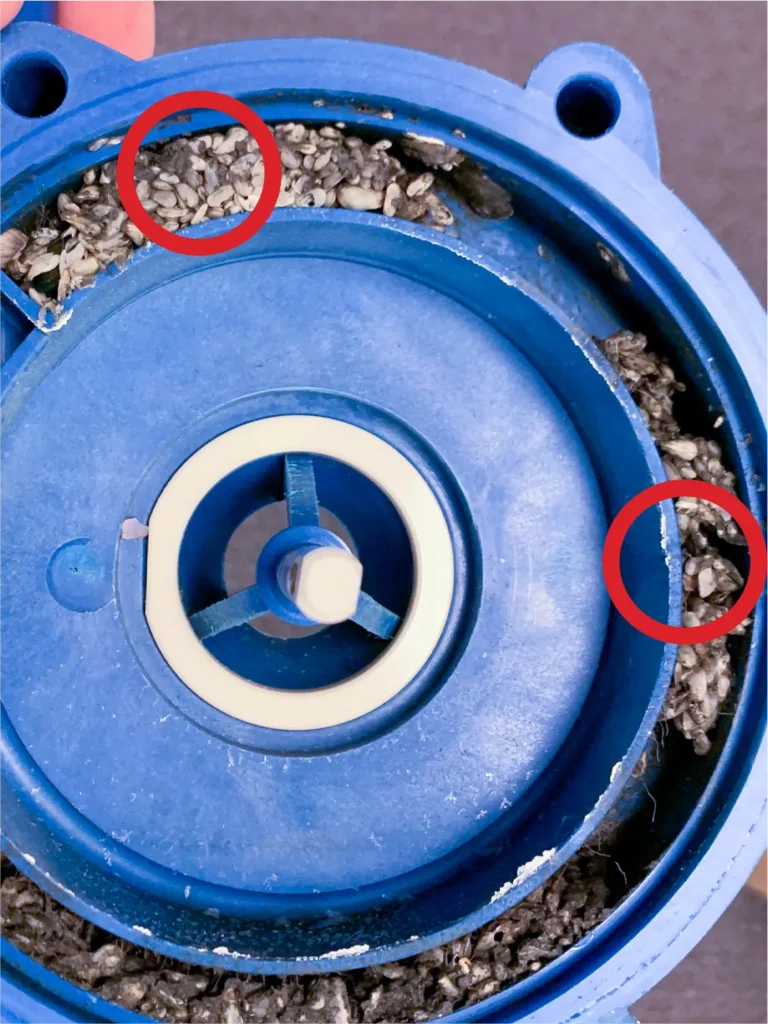

Advanced design prevents growth

The advanced pump head is engineered using Computational Fluid Dynamics to have no low-flow or dead spaces, preventing unwanted growth (patent pending).

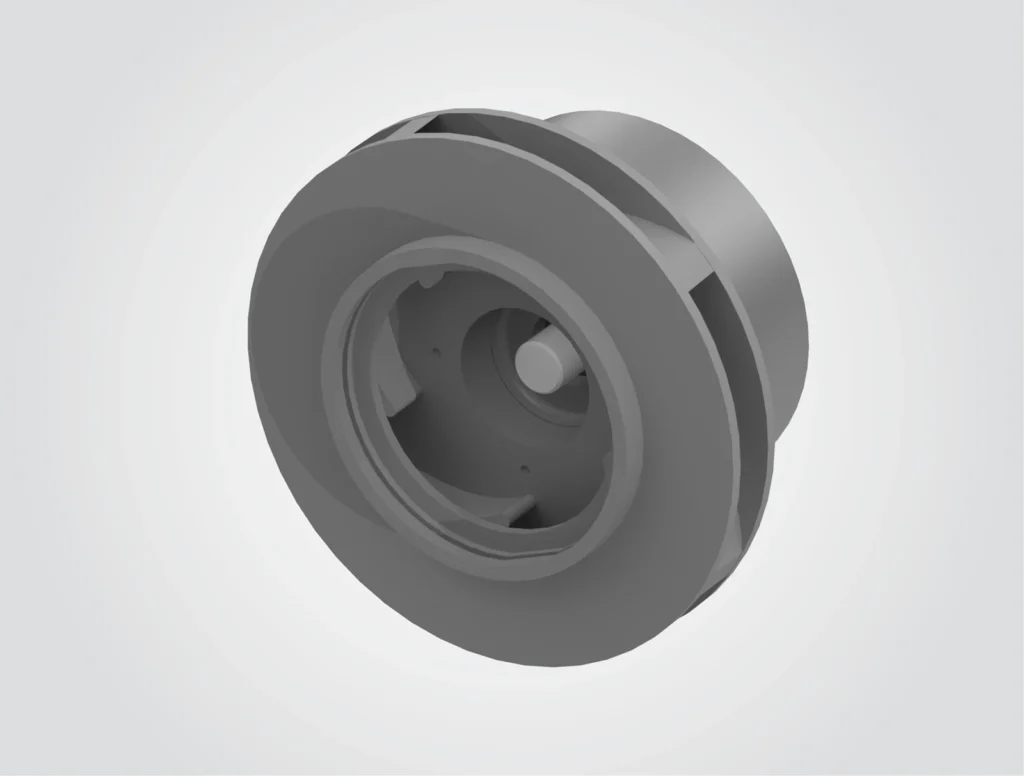

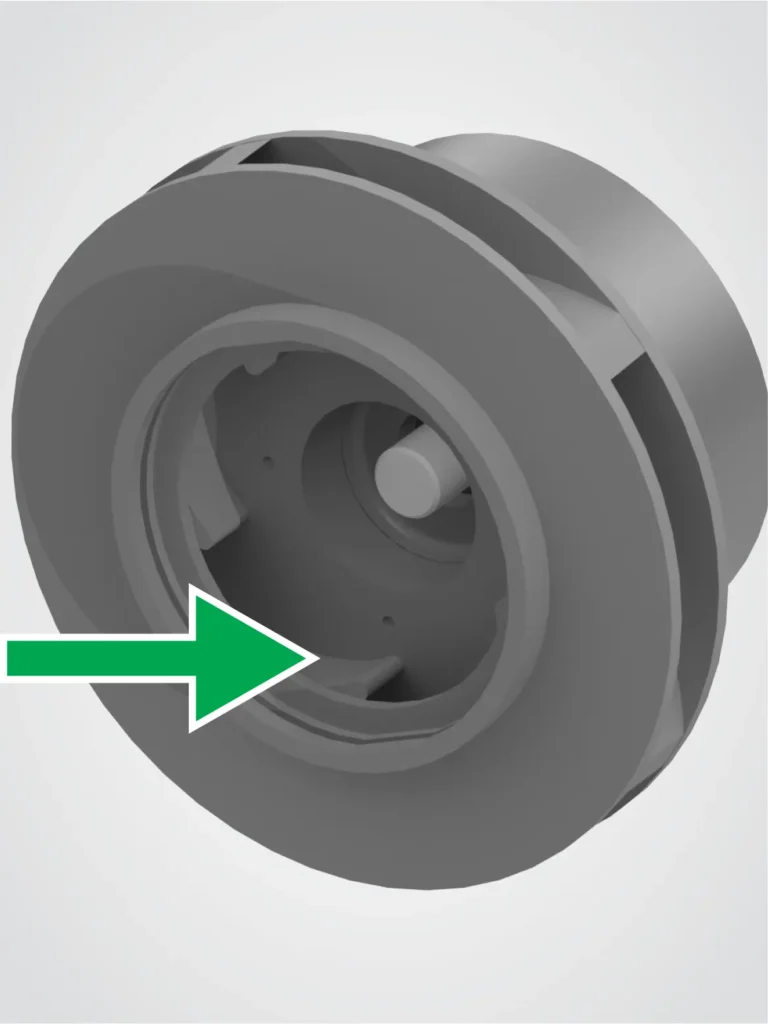

Non-metallic impeller for long life

The long-lasting composite impeller will not wear out or corrode over time, allowing the highly efficient impeller to provide the high flow needed for industrial applications.

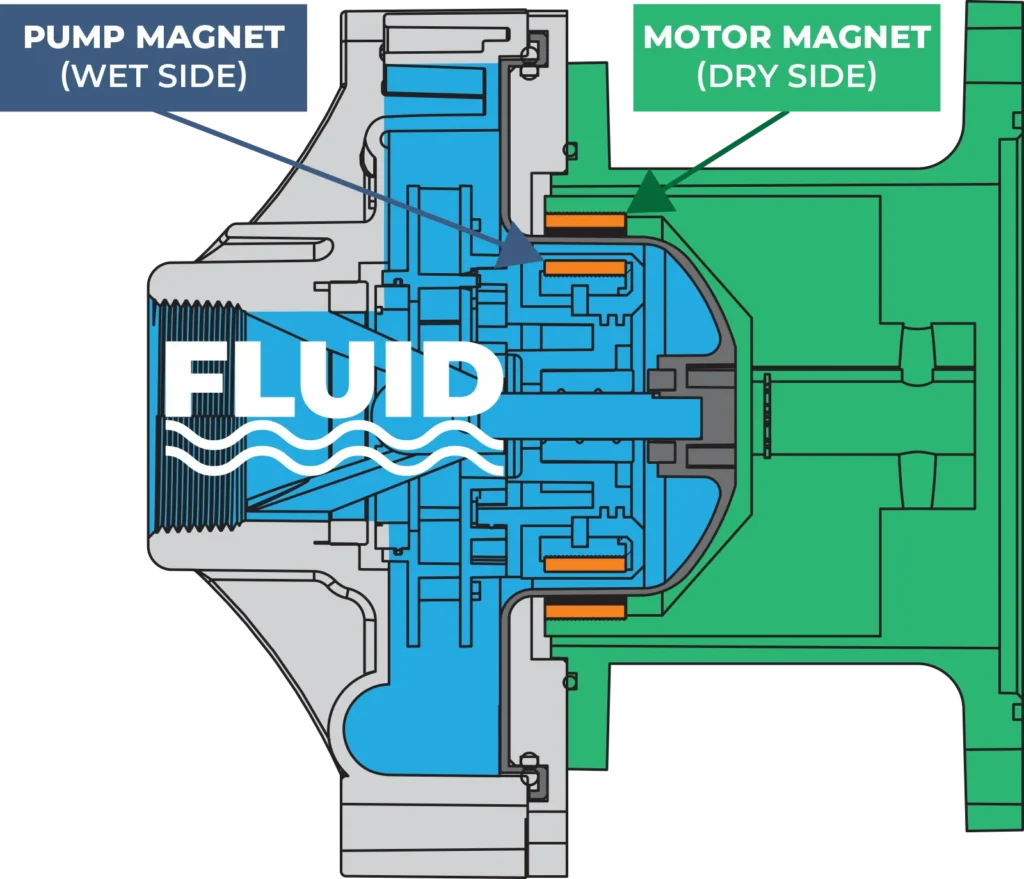

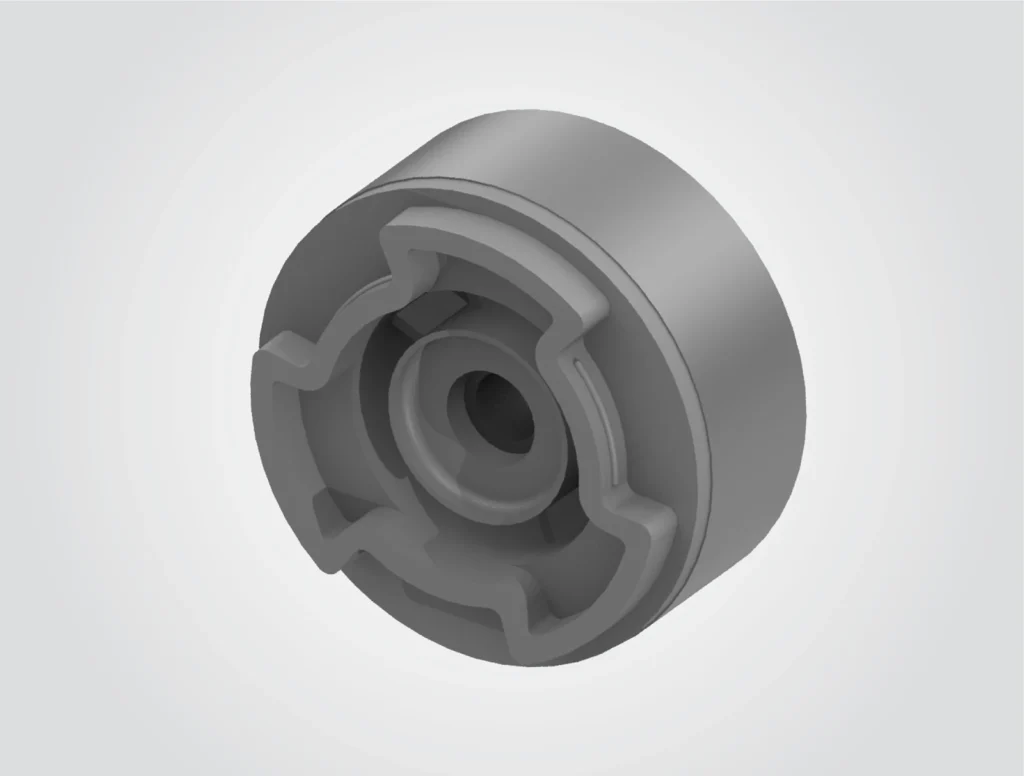

Sealed magnet for maximum drive

A completely sealed, super-strong composite-molded-over-neodymium magnet connects the wet end to the motor drive without any seals.

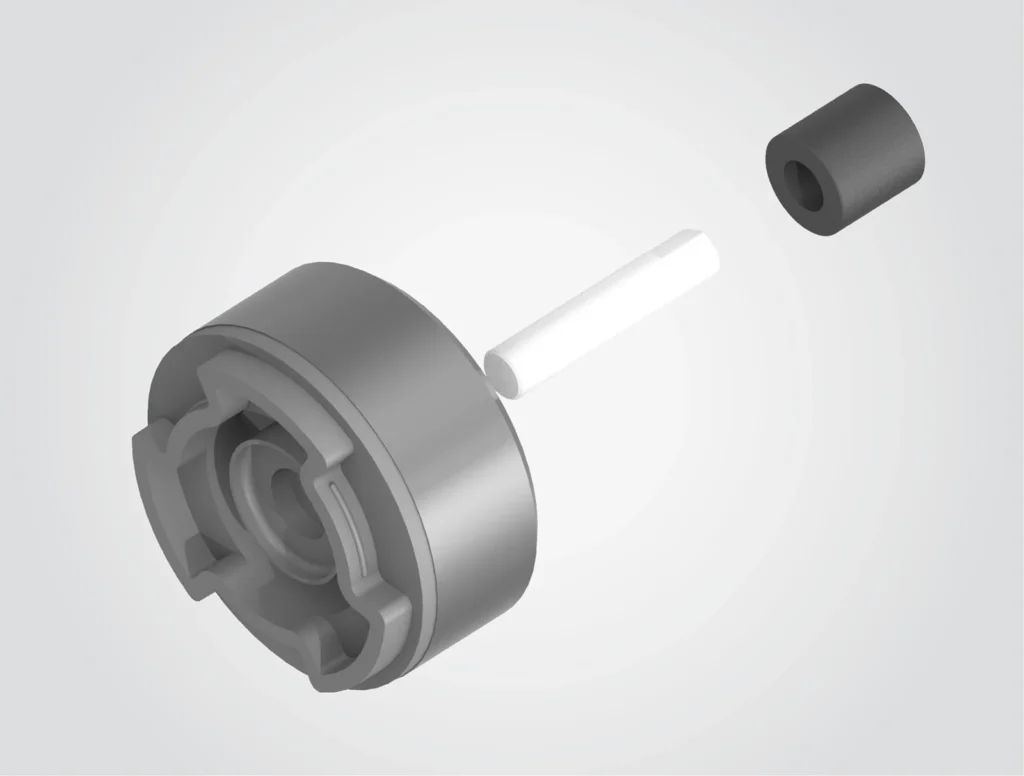

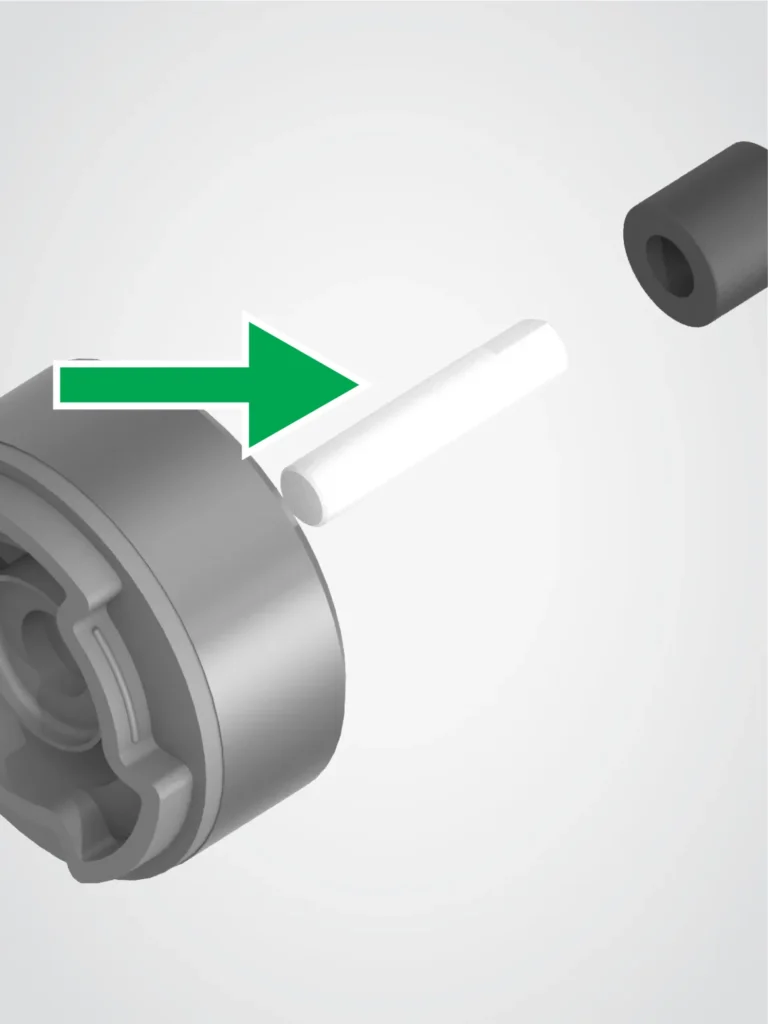

Ultra-low friction shaft and bushings

The ultra-low friction ceramic shaft and carbon graphite bushings are infused with proprietary materials to dissipate heat efficiently for extended life span.

Composite pump head with no metallic parts

The advanced glass fiber-reinforced composite pump head has a high temperature resistance and no metallic parts in the fluid path for superior reliability and longevity.

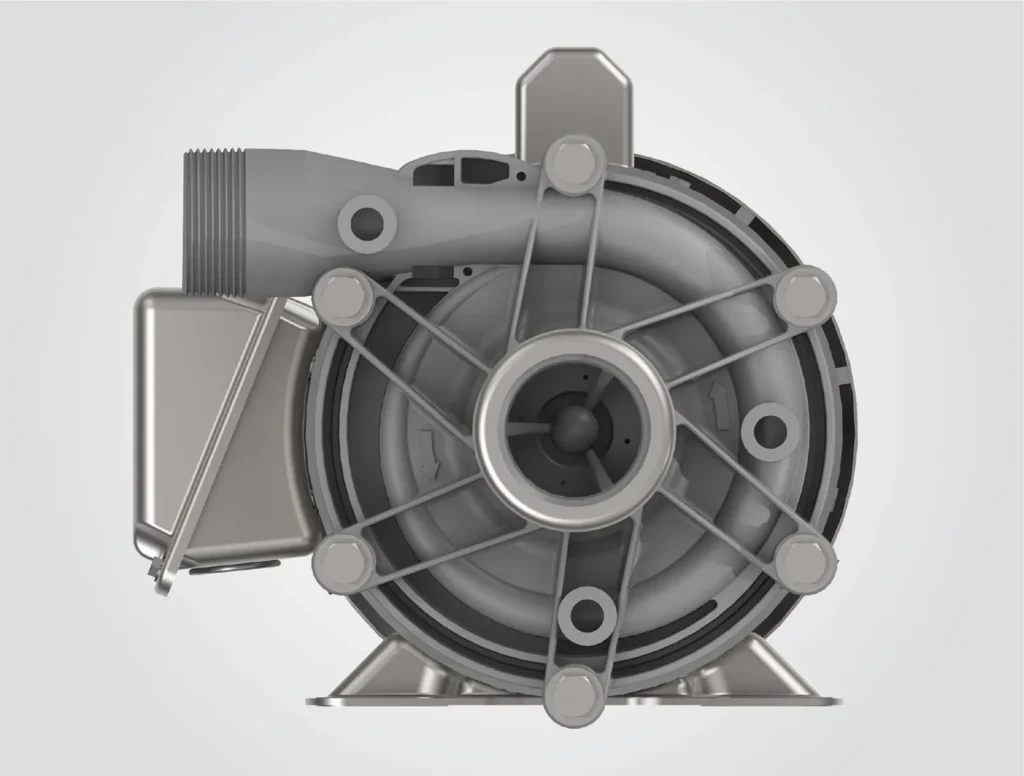

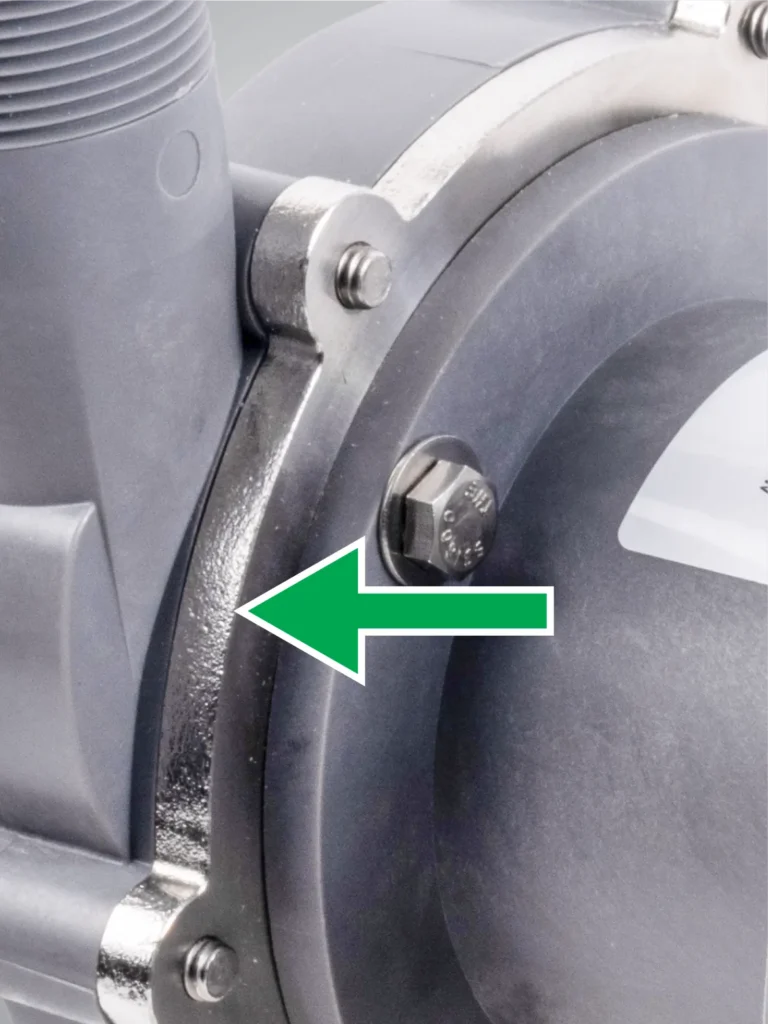

316L stainless prevents corrosion

The high-grade (316L) stainless motor-to-pump connection plate and (316L) hardware prevents corrosion and keeps the pump in tip-top shape.

Rotatable pump head for flexibility

The pump head can be rotated for flexible installations where space for the outlet connection is limited.

Superior performance

At Magnevo, we engineer more than pumps; we engineer solutions. Our pumps are meticulously designed with a focus on innovation, incorporating cutting-edge technology and patent-pending features. Our unwavering commitment to excellence results in the most superior, reliable industrial pumps available on the market today. Our pumps are not merely components; they are the cornerstone of efficient and dependable operations across diverse industries.

Magnevo pumps

Magnevo’s sealless magnetic-coupled design has no mechanical shaft seal and will not leak.

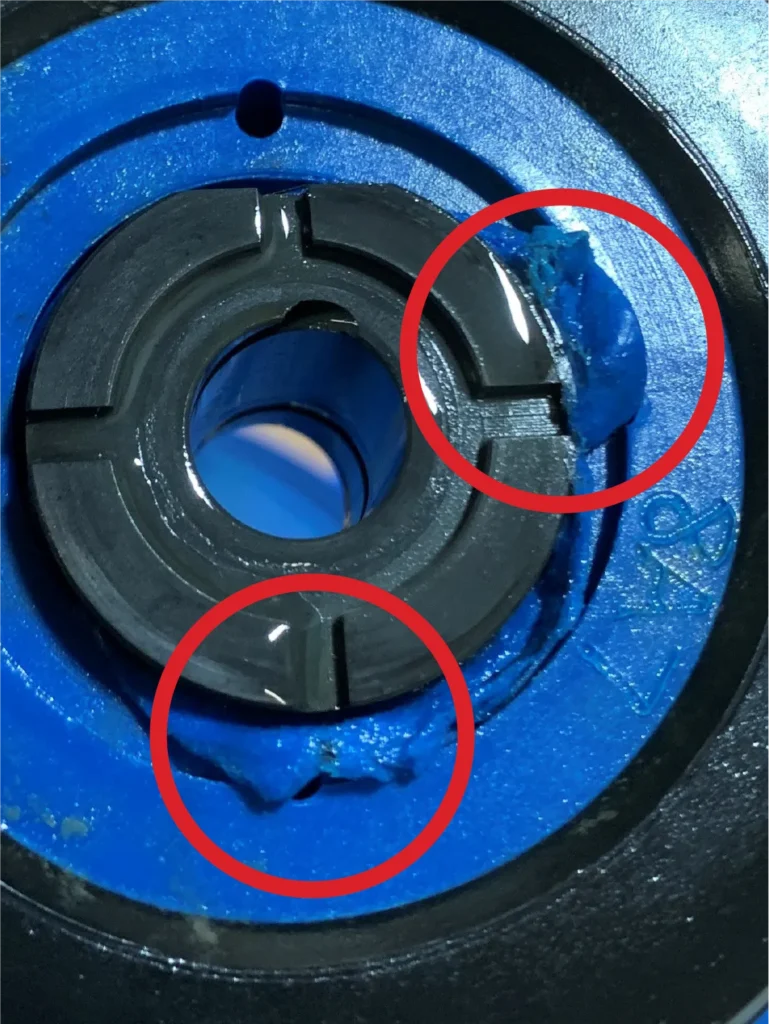

A reinforced inlet ring that is molded into the pump head and made from (316L) stainless provides extra strength at the connection point to prevent cracking. (patent pending)

The advanced pump head has no low-flow or dead spaces, preventing unwanted growth. (patent pending)

The ultra-low friction ceramic shaft and carbon graphite bushings are infused with proprietary materials to dissipate heat efficiently for extended life span.

The glass-fiber reinforced composite pump head has no metallic parts in the fluid path that can corrode or fail.

The high-grade (316L) stainless motor-to-pump connection plate and (316L) hardware prevents corrosion and keeps your pump in tip-top shape.

Other Pumps

Traditional direct-drive pumps leak at the shaft seal, causing them to fail.

Unreinforced heads crack if excessive force is used or if the threads become compromised.

Other pump-head designs facilitate growth with low-flow or dead spots.

Lower-grade composites are more susceptible to overheating, premature wear, and failure due to friction.

Metallic parts in the fluid path are susceptible to corrosion, erosion, cavitation, and eventual failure.

Other pumps use low-grade painted steel hardware that lacks the durability required for demanding industrial applications.